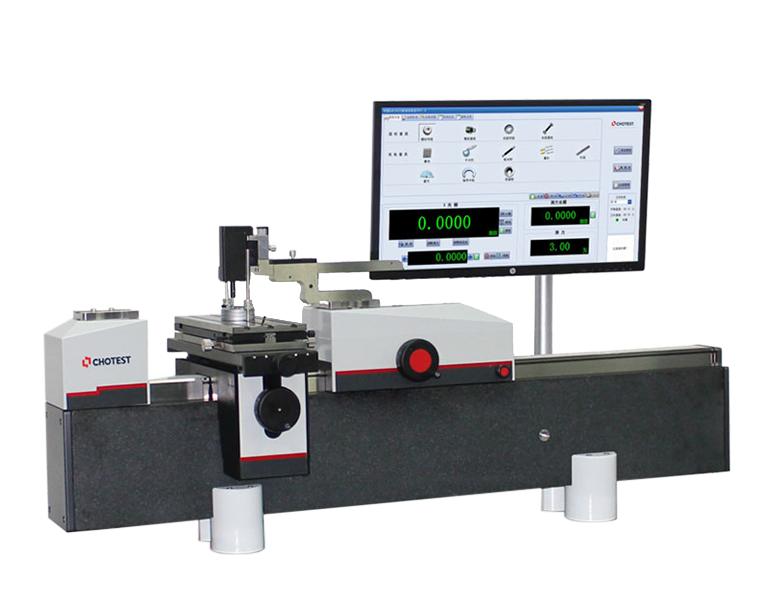

Zero Defect Quality Management

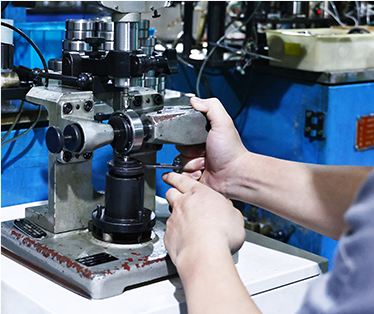

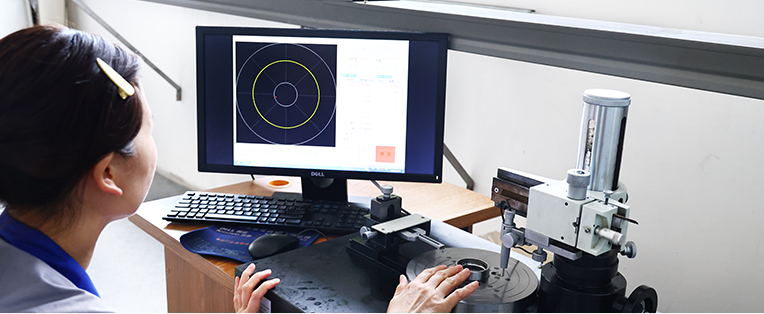

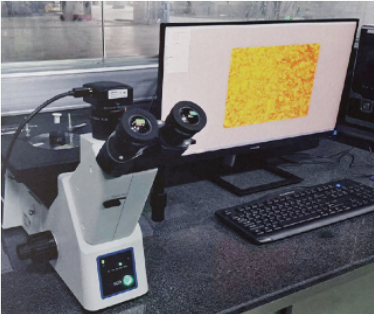

Starting from decision-making, the zero-defect quality principle is implemented in all aspects of investment, research and development, supply, production, marketing and service. "Three No's Principles (Don't accept bad things, don't create bad things, and don't let go of bad things)" is the basic code of conduct for all employees of the company. Unmanned manufacturing, full-line closed-loop processing mode and a complete online error-proofing system provide a solid guarantee for achieving the zero-defect quality goal. Stable and reliable supply of raw materials, robust manufacturing process control and the establishment of IATF16949 quality management system lay the foundation for zero-defect quality management.