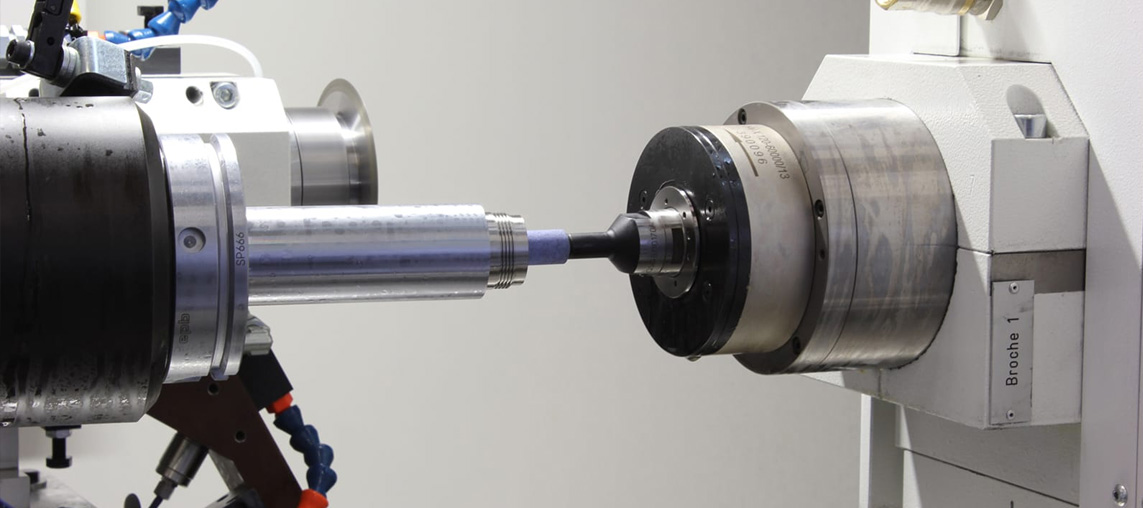

Bearings play an important role in grinding and machine tool processing and are critical to ensuring the high precision and stability of machine tools. The following is the specific role of bearings in grinding and machine tool processing:

1. Support and positioning: Bearings are used to support and position rotating components in machine tools (such as spindles, turntables, etc.) to ensure their accurate position and stable running trajectory when rotating at high speed. The high rigidity and precise performance of the bearings ensure accurate positioning and stable rotation of the machine tool during operation.

2. Carrying torque and load: Bearings must not only bear the torque of rotating parts, but also the loads generated by cutting forces and workpiece loads. Therefore, the bearing must have sufficient load-bearing capacity and stiffness to ensure the high accuracy and stability of the machine tool.

3. Reduce friction and wear: During the grinding and machine tool processing process, which involves high-speed rotation and high temperature, bearings can reduce friction and wear between components and maintain the accuracy and life of the machine tool. Bearings with high-quality lubrication and highly wear-resistant materials can reduce energy losses, extend component life, and reduce maintenance and replacement costs.

4. Reduce vibration and noise: Bearings can reduce vibration and noise during grinding and machine tool processing. High-precision bearings can provide a stable motion platform, reduce vibration and noise of machine tools, and improve grinding and processing quality.

In short, bearings play a vital role in grinding and machine tool processing, which can improve the accuracy, stability and work efficiency of machine tools.

中文简体

中文简体 English

English